Wedoany.com Report-Dec 18,A four-year project has found that using less material in offshore wind turbine construction can reduce the cost per unit of produced energy by up to 9%.

In the HIPERWIND project, EPRI Europe collaborated with DTU Wind and Energy Systems, ETH Zurich, EDF, IFPEN, University of Bergen and DNV to develop methods for turbine loads, maintenance planning, and health and reliability assessments.

By considering the entire design chain, the approach reduced capital expenses, as well as operations and maintenance costs.

That could boost the competitiveness of offshore wind, helping the European Union meet its goal of installing 450GW of offshore wind by 2050.

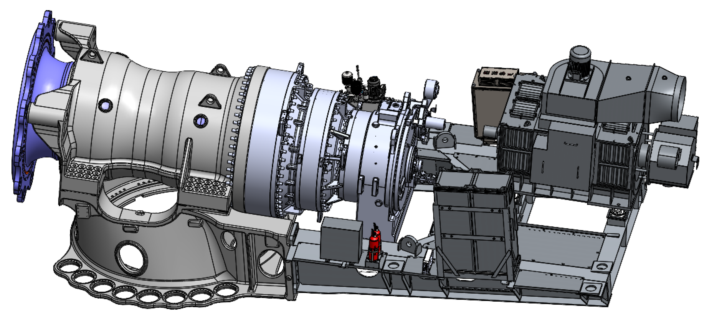

Offshore wind turbines face harsher conditions than their onshore counterparts, necessitating robust designs that often drive up costs, namely the capital costs and the levelised cost of electricity (LCoE).

“The primary achievement of HIPERWIND is the integration of uncertainties into the design process,” said Nikolay Dimitrov, project lead from DTU Wind.

“We explored how to measure and identify different uncertainties, such as environmental conditions, loads, and wind turbine reliability.

“By understanding these uncertainties better, the researchers were able to reduce material usage and lower energy costs.”

Specifically, the project used a real-world case study of the Teesside offshore wind farm in England, owned by EDF.

The team assessed whether improved knowledge could reduce costs if the wind farm were rebuilt.

HIPERWIND highlighted how using less material in turbine construction can reduce upfront costs, which comprise about 30% of the overall cost of energy.

Additional savings were achieved by scheduling maintenance during low energy price periods.

“HIPERWIND could be a game-changer,” said Clement Jacquet, senior researcher in wind farm optimisation of EPRI Europe.

“The methodology has demonstrated the feasibility of designing more efficient systems.

“This adaptable framework could help companies save money on future onshore and offshore wind farms, and ultimately provide consumers with greater cost savings.”

Future research will focus on the development of these developed methodologies in production.