Wedoany.com Report-Dec 25, The research team led by Dr. Eun-Jin Joa of the Korea Institute of Energy Research ( hereinafter referred to as 'Energy Research' ) improved the core components of a bioelectrolyte cell that produces hydrogen using microorganisms in waste, thereby solving the power loss problem of the existing process and opening up the possibility of scaling up the process .

Biogas is a gas produced in the process of microorganisms decomposing organic matter in organic waste . When this is reacted with steam at high temperatures or thermally decomposed, it can produce hydrogen, an eco-friendly energy source, and is thus attracting attention as a promising carbon-neutral technology . However, to date, it has not been commercialized due to the emission of carbon dioxide during the production process and the large energy consumption required to maintain a high-temperature environment .

To replace this, leading countries overseas such as the US and Europe have been actively researching hydrogen production processes using bio-electrolyzers * . The principle is that when waste and electricity are supplied to a bio-electrolyzer, electrons and hydrogen ions generated when microorganisms consume organic matter combine to produce hydrogen gas .

* Bio-electrolyzer : A system that produces energy ( electricity , hydrogen , methane, etc. ) or useful chemicals by combining the biological metabolism of microorganisms with electrochemical reactions. It is gaining attention as an eco-friendly technology that can simultaneously process waste and produce energy.

The bioelectrolyte process is advantageous in terms of both environment and cost as it emits less carbon dioxide than existing processes and can operate in low-temperature environments . However, as the process scales up, the movement path of electrochemical reaction substances increases and resistance increases, which has limitations in that power loss increases .

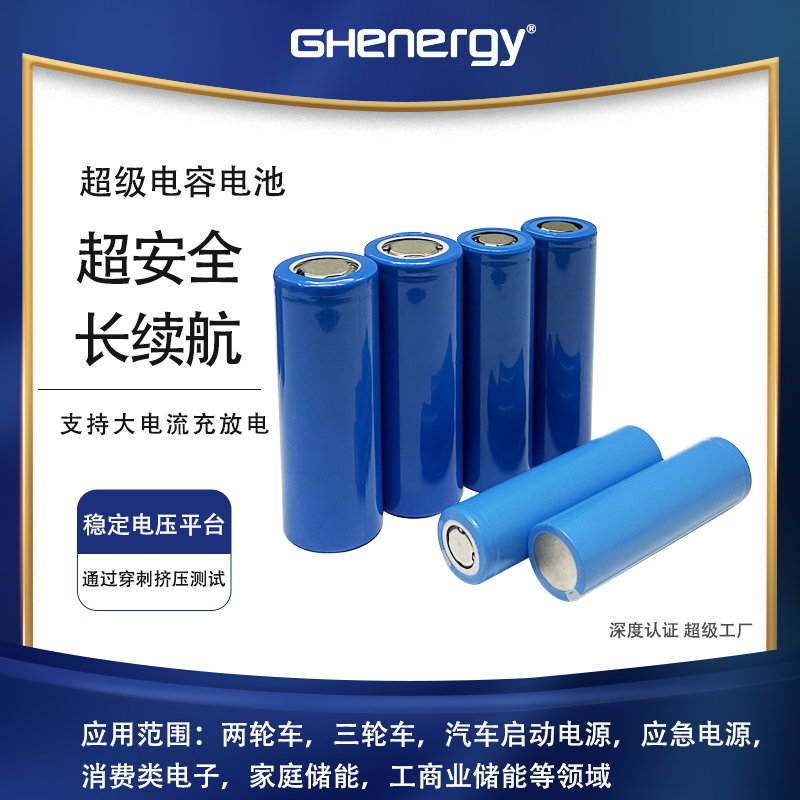

In order to solve the power loss of existing bioelectrolyzers, the research team independently improved the cell, which is the basic unit of the battery, and applied it to the hydrogen production process . The process in which the developed cell was applied showed hydrogen productivity 1.2 times higher and electron productivity 1.8 times higher than that of the hydrogen production process using existing bioelectrolyzers .

The newly developed bioelectrolyte cell uses a new zero-gap technology developed by the research team . Zero-gap is a method frequently used to minimize the gap between the electrodes and separators that make up the battery, thereby reducing electrical resistance and maximizing reaction efficiency .

However, the existing zero-gap structure is simply configured to sandwich the electrodes and membranes together, so when the process is scaled up, a pressure imbalance occurs, creating a small gap between the electrodes and membrane . This causes a partial decrease in efficiency and causes resistance to increase again .

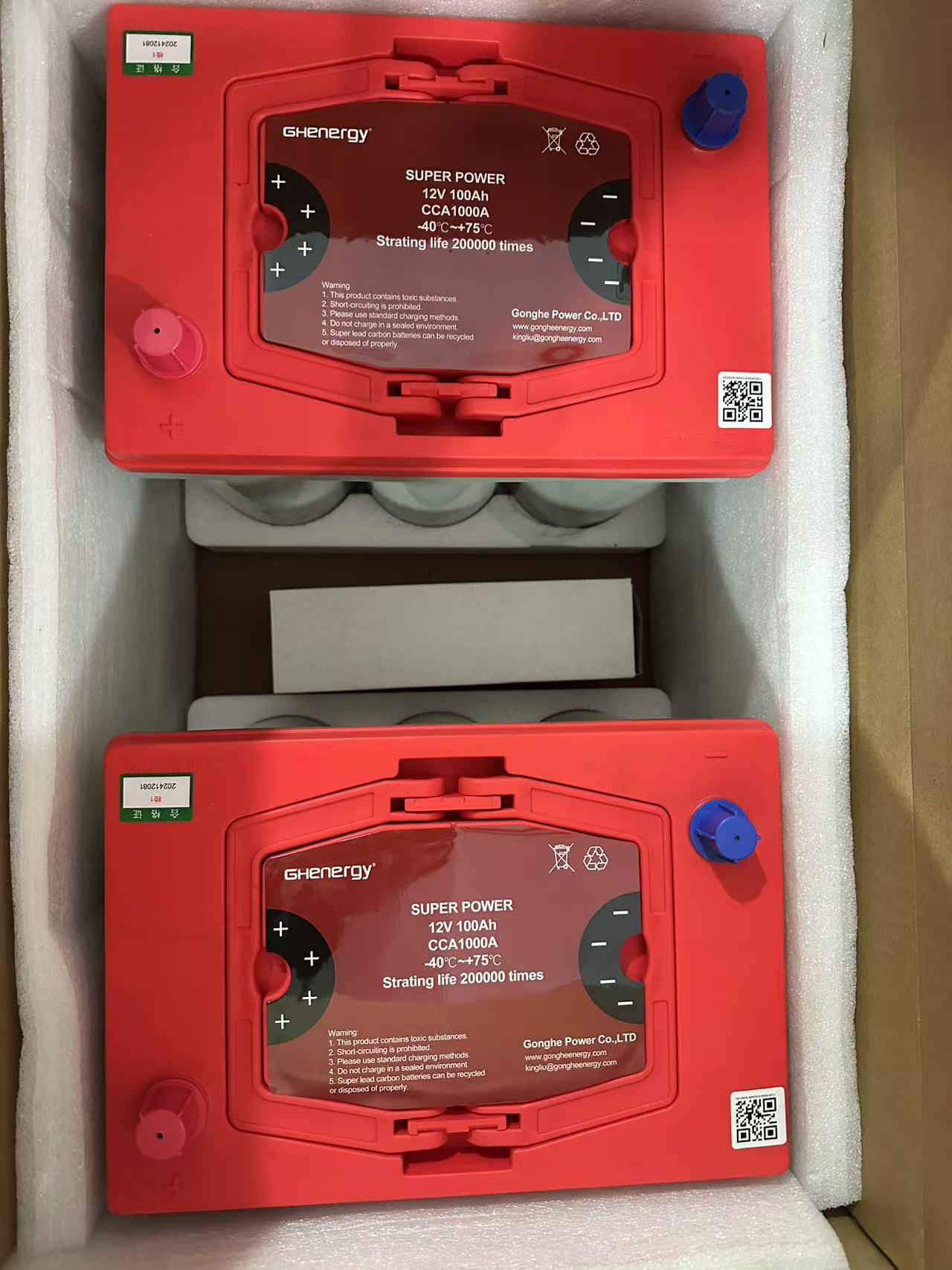

On the other hand, the zero-gap structure developed by the research team has a cylindrical lid, and the pressure generated when the lid is closed can evenly push the back of the electrode, completely sealing the electrode and the separator . Since this can be equally applied when the process is scaled up, it is expected to play a major role in the commercialization of bioelectrolyte cells .

The research team applied the developed bioelectrolyte cell to the hydrogen production process and succeeded in producing 1.8 times more electrons than the existing process and increasing the final amount of hydrogen produced by 1.2 times . The same performance was maintained in the pilot-scale experiment, which is the preliminary stage of large-scale development , and through this, it obtained official certification from the Korea Testing Laboratory and proved its effectiveness .

Dr. Eun-Jin Jo, the principal investigator, said, “This technology development not only solves the environmental and economic problems of domestic organic waste disposal , but also represents a significant advancement in producing hydrogen, a clean energy source, with high efficiency,” and “ If the developed high-performance bio-electrolysis battery cell is commercialized, it will be able to greatly contribute to the transition to carbon neutrality and a hydrogen society . ”

Meanwhile, this research result was carried out with the support of the Future Hydrogen Source Technology Development Project of the National Research Foundation of Korea and was published in ' Science of The Total Environment,' a world-renowned journal in the field of environmental science .