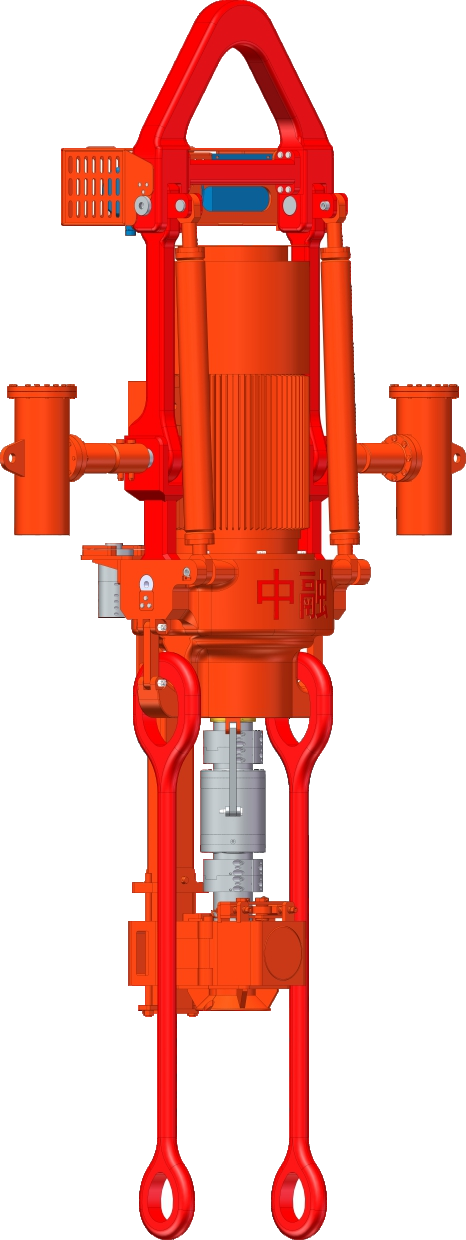

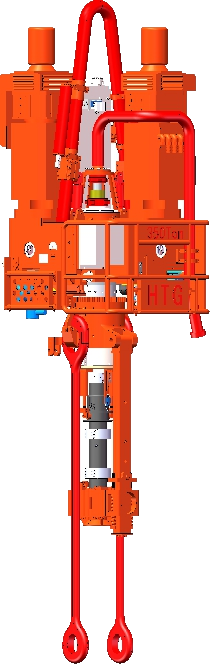

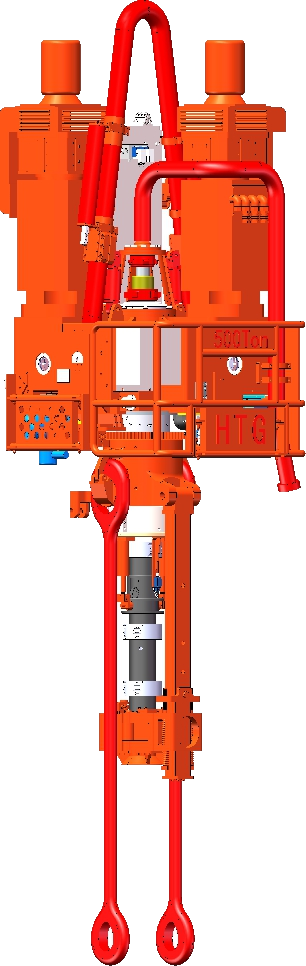

Wedoany.com Report-Nov 1, Conventional wisdom called for drilling four wells into the ground and then horizontally to access layers of oil-soaked rock, a technical feat perfected by the US shale industry. But the plot of land was too narrow, limiting each well’s reach and likely making them unprofitable. So the engineers tried a novel concept: a U-turn. After boring vertically to the shale layer, they went sideways for one mile, curved the well around and then drilled back to where it began. It worked. Matador was able to pump the oil with two wells instead of four, essentially cutting costs in half.Matador Resources Co. encountered a problem.

Conventional wisdom called for drilling four wells into the ground and then horizontally to access layers of oil-soaked rock, a technical feat perfected by the US shale industry. But the plot of land was too narrow, limiting each well’s reach and likely making them unprofitable. So the engineers tried a novel concept: a U-turn. After boring vertically to the shale layer, they went sideways for one mile, curved the well around and then drilled back to where it began. It worked. Matador was able to pump the oil with two wells instead of four, essentially cutting costs in half.

“It’s astounding, really,” says Matador Chief Executive Officer Joseph Foran. “You give people a target, and they’ll find out better ways, better equipment, better techniques.” The U-turn, or horseshoe well, is an example of the small improvements that together have pushed oil and gas producers to the biggest labor productivity gains of any US sector over the past decade—including even tech-related industries, which have historically ranked first. The nation’s crude output has risen to a record 13.3 million barrels a day, 48% more than Saudi Arabia. All with less than a third of the rigs and far fewer workers than were needed 10 years ago.