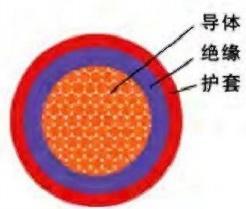

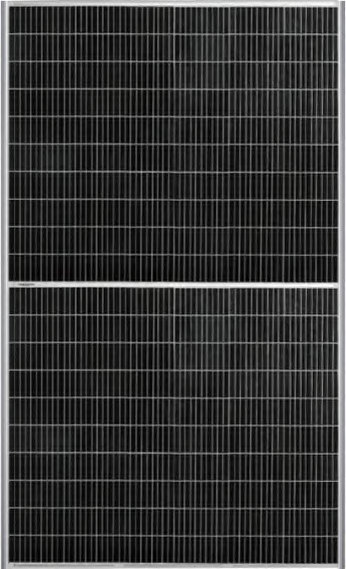

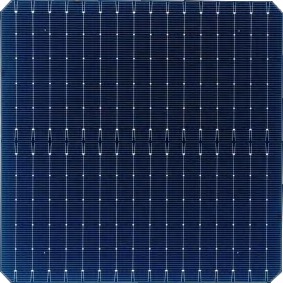

Wedoany.com Report-Dec 14, The German research institute said it is currently exploring three copper metallization methods: Screen printing, FlexTrail printing and rotary printing. The proposed technology is reportedly compatible with either TOPCon or heterojunction bottom cells.

Researchers at the Fraunhofer Institute for Solar Energy Systems ISE (Fraunhofer ISE) in Germany are developing copper metallization technology to avoid using silver in perovskite-silicon tandem devices.

“In brief, we will develop a perovskite-silicon tandem device using printed copper instead of silver. The exclusive FlexTrail printing technique from ISE will be essential. We are collaborating with partners from PV and printed electronics to create a technological advantage for PV production in Europe,” Roman Keding, head of the printing technology group within the Fraunhofer ISE Photovoltaics' division, told pv magazine.

The project, known as Kumelle, will explore three copper metallization methods: Screen printing, FlexTrail printing and rotary printing. The rotary printing study will address two variants: flexographic printing and indirect gravure printing.

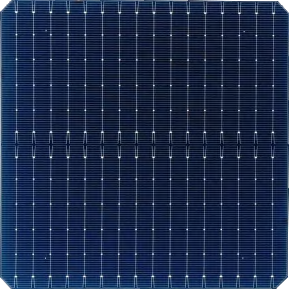

The proposed technology is reportedly compatible with either TOPCon or heterojunction bottom cells. “Everything will be validated and demonstrated in Fraunhofer ISE’s PV-TEC and the Pero-Si-SCALE technology platform,” said Keding, referring to the perovskite-silicon tandem research scaling facility initiated in 2023, to provide researchers with production, characterization, and analysis tools and technology.

“We expect a technology readiness level (TRL) of 6,” said Keding. The TRL measures the maturity of technology components for a system and is based on a scale from one to nine, with nine representing mature technologies for full commercial application.

The project has received funding of €3.2 million ($3.3 million) from the energy research programme of the Federal Ministry of Economic Affairs and Climate Action (BMWK).

The project partners are Germany-based acp systems AG, ContiTech Deutschland Center for Functional Printing Technologies, Elantas Europe GmbH, Eckart GmbH, Saralon GmbH. There are two further associated partners: Qcells Technology and Innovation Center in Germany and Israel-based PV Nanocell.

Earlier this year the same Fraunhofer group demonstrated the use of indirect gravure printing for metallization of silicon heterojunction solar cells.