Wedoany.com Report-Jan 15, AUC Riverside engineering professor will oversee a multidisciplinary team spanning academia and industry that has been awarded a $6 million federal grant to develop advanced catalytic technology to reduce Earth-warming methane pollution in the production of liquefied natural gas (LNG).

Fudong Liu, an associate professor of chemical and environmental engineering, will lead a forty-four months’ collaborative effort involving faculty from Yale University and scientists from HighT-Tech, a Maryland-based advanced manufacturing startup specializing in electrified thermal shock production of catalysts, and BASF, the world’s leading chemical company.

The $6 million grant is provided by the U.S. Department of Energy (DOE) and the U.S. Environmental Protection Agency (EPA). With additional financial support from the participating universities and companies, the project will total $7.5 million.

“Our work will not only reduce greenhouse gas emissions but also advance catalytic science and strengthen the U.S. leadership in clean energy technologies,” said Liu, who joined UCR’s Bourns College of Engineering in January 2024.

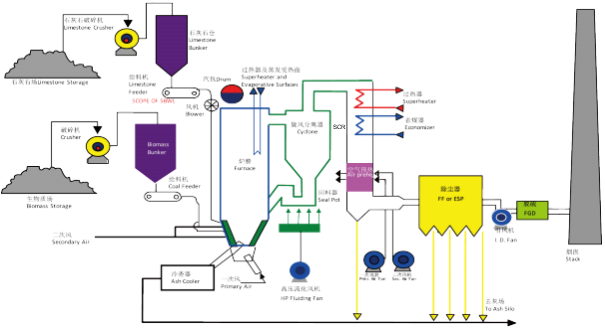

The production of LNG involves burning significant volumes of natural gas as fuel to run industrial-scale engines that push natural gas through compressors with refrigerants, cooling it to a liquid state at about -161 °C (-258 °F). These engines do not burn their fuel completely, resulting in methane emissions. Compared to carbon dioxide, an equal amount of methane has 28 times or more global warming potential once released into the atmosphere.

The research team aims to create industrial-scale catalytic converters made from palladium (Pd)-based materials to nearly eliminate methane through oxidation. These catalysts will be produced using a high-temperature shock technique pioneered by Yale University professor and co-principal investigator Liangbing Hu. This rapid heating and cooling process enables the formation of highly stable catalytic structures.

Robert Gatte, CEO of HighT-Tech, Inc., will lead the scale-up of the innovative and eco-friendly HTS manufacturing to enable efficient production process of catalysts impossible before. The catalytic converters, designed with advanced washcoated honeycomb structures to maximize surface area and enhance catalytic reactions, will be developed under the supervision of Yuejin Li, senior Principal Scientist at BASF Environmental Catalyst and Metal Solutions.

“Our goal is to design catalysts at the atomic level to maximize their performance,” Liu explained. “We’ll then scale up production and validate their effectiveness in real-world conditions.”

The catalysts will undergo testing at natural gas well sites.

“This project exemplifies how partnerships between academia, industry, and government can drive meaningful change,” Liu said. “I’m excited to see what we can achieve together.”

The project is one of 43 that collectively received in December about $850 million in grants from the DOE and the EPA to reduce, monitor, measure, and quantify methane emissions from the oil and gas industry.

Since joining UC Riverside in January 2024, Liu has secured more than $4.2 million funding to his research group at the Department of Chemical and Environmental Engineering within his first year, from DOE, EPA, the National Science Foundation, and BASF.

Among his achievements, Liu and team at the Bourns College of Engineering and the College of Natural & Agricultural Sciences were awarded a $3.18 million EPA grant to develop a scalable catalytic method with assisting technologies to reduce hydrofluorocarbon pollution from air conditioning systems. Like methane, hydrofluorocarbon emissions are potent contributors to global warming.