Wedoany.com Report-Nov 29, Researchers in China have suggested to combine PV plants with direct air capture (DAC) technologies in an effort to reduce solar curtailment and increase DAC competitiveness. They found that the proposed combination could become viable by 2030, especially if carbon prices will increase.

Scientists from the Shanghai Jiao Tong University in China have proposed to couple PV power plants with direct air capture (DAC) systems with the aim of reducing PV curtailment due to excess solar power across electricity grids.

“Combining PV and DAC could be feasible regardless of any approach intended to reduce curtailment,” the research's lead author, Miao Yihe, told pv magazine. “However, using curtailment can decrease the operational cost of DAC, which would contribute to its early development.”

DAC systems remove carbon from the atmosphere via both chemical and physical processes. Large-scale DAC systems, however, remain challenging due to difficult material development and process construction. Moreover, significant energy intensity restricts their widespread adoption. “Although the current deployment of flexible adsorbent-based DAC does not yield positive returns, its economic benefits and emission reduction potential will gradually emerge as carbon prices increase and adsorbent costs decrease in the future,” Yihe stated.

In the study “Addressing solar power curtailment by integrating flexible direct air capture,” published in Carbon Capture Science & Technology, the researchers explained that their approach consisted of making PV-driven DAC systems participate in minute-level dispatch, which in turn allows the DAC to better match the fluctuation of PV plant.

The group assumed the flexible DAC units to be designed modularly, which allows each unit to operate as an independent load without the need for continuous operation, while also enabling interruptions between cycles or processes. Additionally, the curtailable and extendable adsorption process enables dynamic adjustment of the activation time for the desorption process. “Each unit can operate independently, reducing the dependency of the overall system on a continuous power supply,” it further explained. “These devices can dynamically start up or shut down based on the intermittency and availability of solar power.”

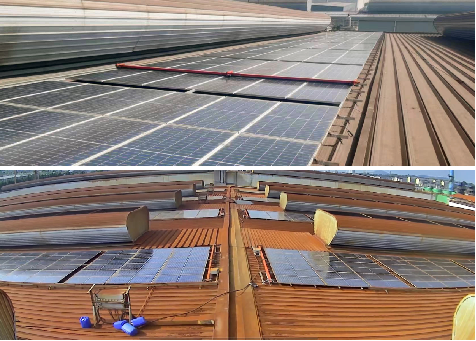

The academics conducted a comparative techno-economic analysis of deploying DAC and battery energy storage (BES) systems at a 1 GW solar power plant located in Qinghai Province, China. The facility was commissioned in 2023 and is linked to a 200MW/255MWh lithium iron phosphate (LiFePO4) BES system. The DAC system is assumed to be based on temperature vacuum swing adsorption (TVSA) processes to capture CO2 from air.

“The energy requirements are met through power curtailment or electricity purchased from the grid, with a strategy that prioritizes the use of zero-cost power curtailment and supplements with grid electricity as needed,” the team specified. “The BES systems charged or discharged as needed, providing auxiliary peak shaving services to the grid.“

The research team explained that the adsorption process adopted for the DAC system is curtailable and extendable. This means that, when the power curtailment is insufficient and using grid electricity is not economically viable, the system can extend the adsorption time up to a maximum of two hours before desorption to reduce operational costs, while dynamically adjusting operations based on power availability.

The analysis showed that the DAC system can achieve the lowest cost in utilizing power curtailment and capturing CO2. “Case analysis results indicate that flexible DAC is the most cost-effective solution, and the flexible operation strategy enables DAC to be compatible with the intermittency of PV without the need for BES,” the academics emphasized. “Deploying BES in addition to flexible DAC does not produce positive impacts but diminishes the ability of flexible DAC to address the curtailment issue.”

The team believes that the combination of DAC and PV could become viable by 2030, especially if carbon prices gradually increase and adsorbent costs decrease.