Wedoany.com Report-Jan 10, SolarPanelRecycling.com (SPR) has announced the launch of a new solar panel recycling line that promises “unprecedented efficiency” in separating bifacial modules, the emerging industry standard.

According to SPR, its new line is the first in the United States to enable clean glass separation of bifacial modules at recovery rates of 99% or higher.

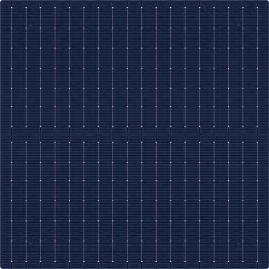

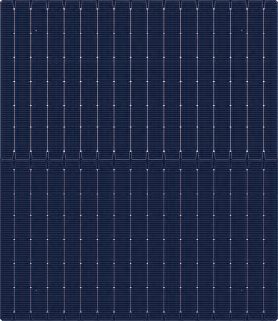

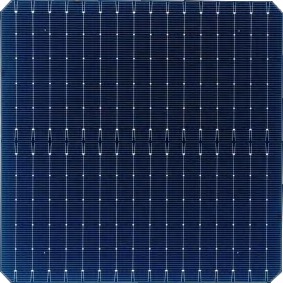

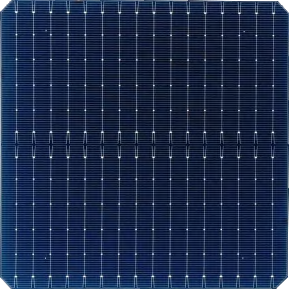

Bifacial modules are expected to account for more than 70% of the global market by 2033. They’re a favorite in the growing utility sector due to higher efficiencies and energy yields than their monofacial counterparts.

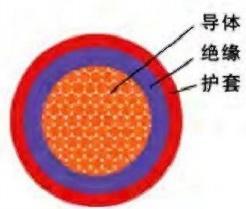

However, SPR identified inefficiencies in monofacial recycling lines that presented problems for bifacial modules, particularly around glass recovery rates and manual labor. That prompted the Salisbury, North Carolina-based company to task its engineers and R&D teams with developing a proprietary new line with “unmatched recovery efficiency.” Unlike partial recyclers who shred whole panels, commingling silicon, glass, metals, and plastics into a hodgepodge of unusable waste, SPR says its process ensures clean separation of all components. This approach epitomizes true recycling, SPR boasts, as each material is returned to the manufacturing supply chain, significantly reducing waste and supporting a circular economy.

“The future of solar recycling demands innovation and SPR is committed to leading the way by establishing best practices. Our investment in a dedicated bifacial recycling line is a proactive step to ensure that our recycling services are scalable and that we can maximize recovery, minimize waste and support the sustainability goals of the industry,” said Brett C. Henderson, CEO of SolarPanelRecycling.com. “True solar recycling goes beyond shredding panels. It requires cleanly separated commodities that can re-enter the supply chain, creating real value and minimizing environmental impact. This new technology marks a major milestone for SPR and for the solar industry as a whole.”

SPR, which has an annual recycling capacity of more than 100 million pounds, says it is already experiencing an uptick in bifacial solar panels hitting the recycling stream due to the panels sustaining damage during transportation, installation, or in extreme weather.

SolarPanelRecycling.com opened a new 300-megawatt recycling center in Breckenridge, Texas in 2024. It is equipped with technology that the company says fully extracts all materials for reuse, including panels, inverters, cabling, and batteries.

The Texas locale is SPR’s fourth domestic processing and receiving plant, joining two locations in North Carolina and one in Georgia.

In the aftermath of Hurricane Helene last October, SPR opened the docks at both of its recycling facilities in its home state of North Carolina to collect non-perishable food, clothing, baby supplies, water, sports drinks, pet food, flashlights, gas cans, batteries, hygiene products, and more. The company utilized its fleet of trucks to transport collected goods directly to needy communities in Western NC.

SPR donated 100 working solar panels to Asheville’s Land of Sky Regional Council and mobilized its maintenance technicians and heavy equipment operators to work alongside the West Yancy Fire Department hiking unpassable roads, fixing generators, making temporary passings, and reaching stranded households. SPR employees even helped clear fallen trees in Western NC and performed wellness checks on people known to be stuck without power.

“Witnessing the heartbreaking devastation in WNC, it was clear we had to step in—without hesitation,” said Henderson at the time. “We were ready to do whatever we could to support the community.”