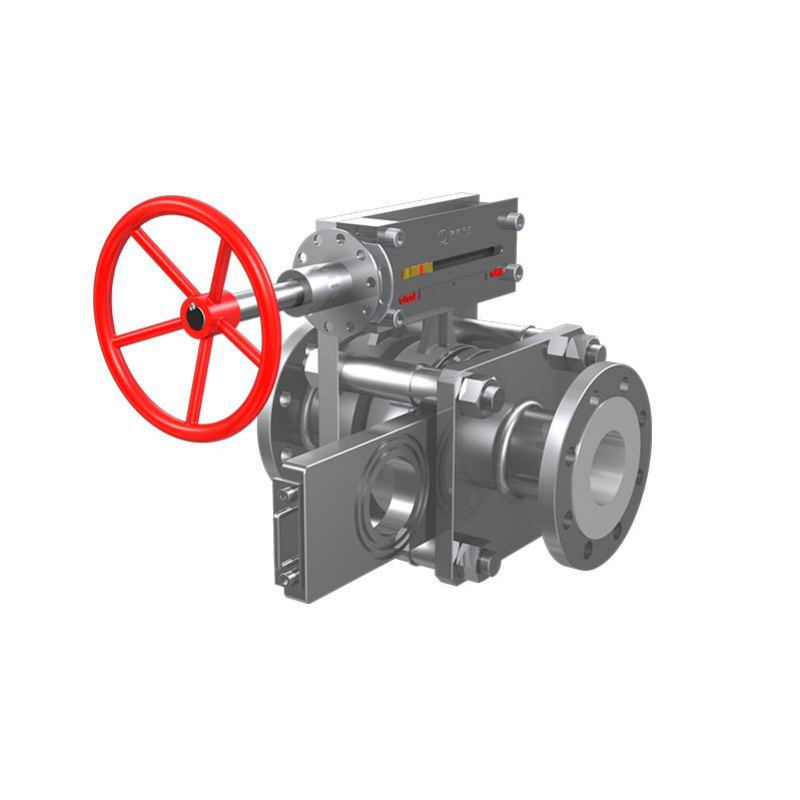

The new type of pipeline quick-acting blind flange uses a unique and simple switching mechanism. One person can easily, quickly, and safely perform shut-off operations on critical pipelines without any tools or lifting equipment, saving labor costs and extending production uptime.

The new type of pipeline quick-acting blind flange uses a unique and simple switching mechanism. One person can easily, quickly, and safely perform shut-off operations on critical pipelines without any tools or lifting equipment, saving labor costs and extending production uptime.

In the closed state, no liquid or gas leaks to the downstream.

For large-diameter pipelines, shut-off can be achieved safely within 30 seconds to 2 minutes. Using a quick-acting blind flange valve for shut-off reduces labor intensity, requires fewer personnel for the operation, and eliminates danger. The structure is simple, durable, and easy to maintain.

Technical Parameters

Size: DN50-DN1000

Pressure: PN6-64; Class 150/300

Material: WCB (A105), LCB, CF8 (304), CF8M (316), CF3 (304L)

Sealing Surface: Fluororubber, flexible graphite

Connection: Flange, welded

Turbine Drive: Manual, electric

Product Applications

Power, petrochemical, steel, marine facilities, metallurgy, and other industries