To prevent faults in the arc extinguishing chamber and fuse from affecting the normal operation of other circuits, a visible isolating breaker is installed in front of the arc extinguishing chamber. It is divided into two parts and installed in different compartments. In the event of a problem, safe maintenance and repair can be performed while other circuits continue to operate, improving work efficiency and facilitating maintenance.

Product features:

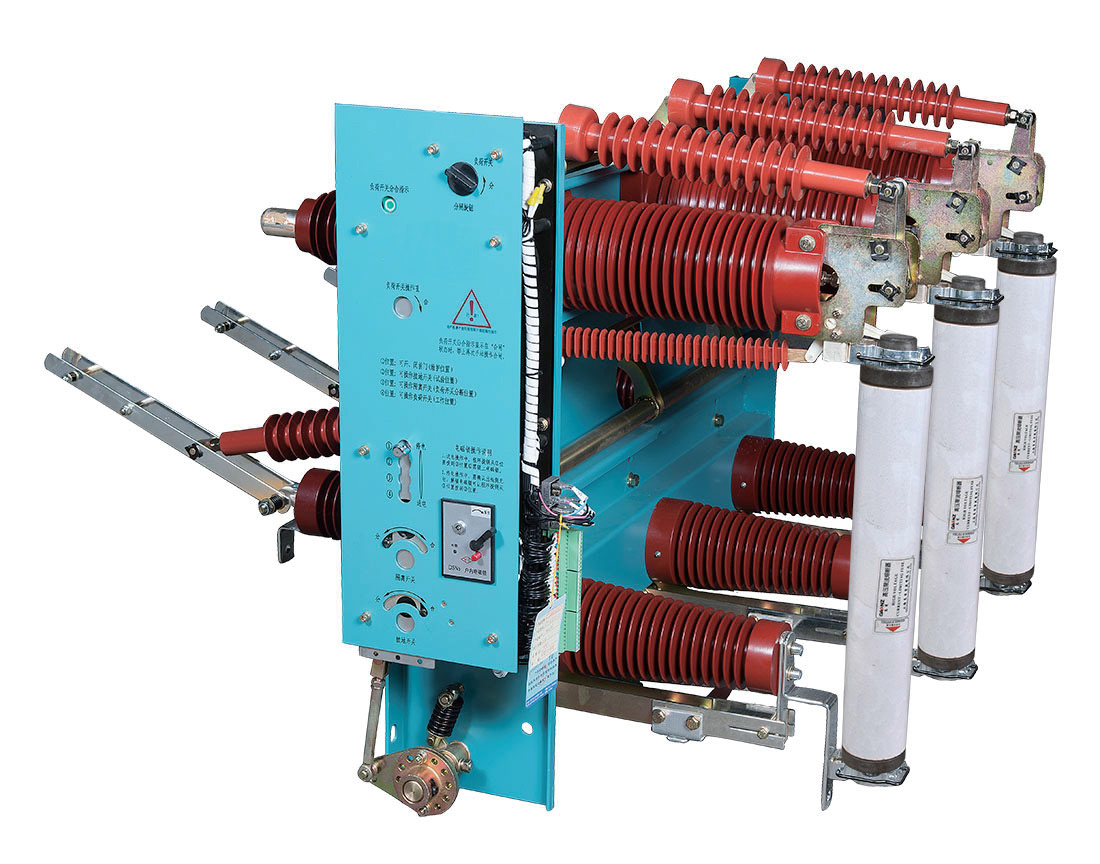

① To prevent faults in the arc extinguishing chamber and fuse from affecting the normal operation of other circuits, a visible isolating breaker is installed in front of the arc extinguishing chamber. It is divided into two parts and installed in different compartments. In the event of a problem, safe maintenance and repair can be performed while other circuits continue to operate, improving work efficiency and facilitating maintenance. The fuse and isolating switch are installed on the left and right sides of the switch. When replacing the fuse, the isolating switch is opened after the arc extinguishing chamber is separated, providing sufficient safety distance between the high-voltage side and the maintenance personnel, making it more convenient and safe.

② The arc extinguishing chamber uses solid-sealed pole columns, employing advanced Automatic Pressure Gelation (APG) technology to directly seal the vacuum arc extinguishing chamber and other main circuit components in epoxy resin. This not only improves the assembly process of the pole columns and prevents loosening of the vacuum arc extinguishing chamber’s conductive circuit bolts due to vibrations during operation, thus improving reliability, but also protects the vacuum arc extinguishing chamber from external mechanical forces and environmental influences (such as dust, moisture, pollution, high altitudes, and small animals), further improving the electric field distribution of the pole columns.

③ The load switch and isolating switch operate independently, but all three devices have reliable mechanical interlocks to prevent misoperations.

④ A dedicated spring operating mechanism is installed to ensure closing is powered by a stored energy spring. It can be charged either electrically or manually, making it labor-saving and convenient, and it also enables automatic control.

Application range:

The FZ16-40.5 and FZ16-40.5R are suitable for use in power networks with a rated voltage of 40.5kV and a frequency of 50Hz. They can interrupt load currents, overload currents, and short-circuit currents. The XGZ16 is specifically designed for 40.5kV box-type substations and small secondary distribution stations, particularly suitable for the control and protection of terminal transformers. It is the best choice for high-voltage collection and grid connection in renewable energy applications such as wind power, photovoltaic power generation, and energy storage.