The inverter system drives the three-phase AC motor to control the movement of the shuttle car. The two inverters provide adjustable voltage and adjustable frequency power to the traction motor. The inverter system applies power electronics technology to convert AC to DC (rectifier), which is then filtered by a DC filter. After smoothing, the DC is converted back into AC (inverter), realizing the output of variable voltage and variable frequency (VVVF). When the 24Vdc control voltage is supplied to the corresponding start-up pins (XENBL) of the two inverters, the inverters begin communication with the central controller through the bidirectional serial interface. The pump contactor engages, and each inverter’s input bridge is fed with line voltage.

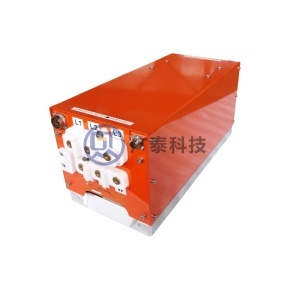

Matched models: 10SC32/10SC32-48

Product introduction:

The inverter system drives the three-phase AC motor to control the movement of the shuttle car. The two inverters provide adjustable voltage and adjustable frequency power to the traction motor. The inverter system applies power electronics technology to convert AC to DC (rectifier), which is then filtered by a DC filter. After smoothing, the DC is converted back into AC (inverter), realizing the output of variable voltage and variable frequency (VVVF). When the 24Vdc control voltage is supplied to the corresponding start-up pins (XENBL) of the two inverters, the inverters begin communication with the central controller through the bidirectional serial interface. The pump contactor engages, and each inverter’s input bridge is fed with line voltage. The foot switch is operated, and each inverter’s output bridge supplies voltage to the traction motor, causing the shuttle car to accelerate. The direction of movement of the shuttle car is determined by the driver’s operation of the foot switch and the travel direction switch next to the shuttle car’s side seat. The motor’s efficiency and performance depend on the motor current characteristics, with the use of pulse width modulation (PWM) and high-frequency conversion (10kHz to 20kHz) to achieve a nearly smooth current sine wave. The motor’s rotation direction is controlled by the IGBT inside the inverter. The IGBT relies on switching sequences to transmit power in both directions.