9-26 high-pressure fan is typically used for forging furnaces and high-pressure forced ventilation. It can also be widely used for material transport, air delivery, and conveying non-corrosive, non-combustible, non-viscous gases.

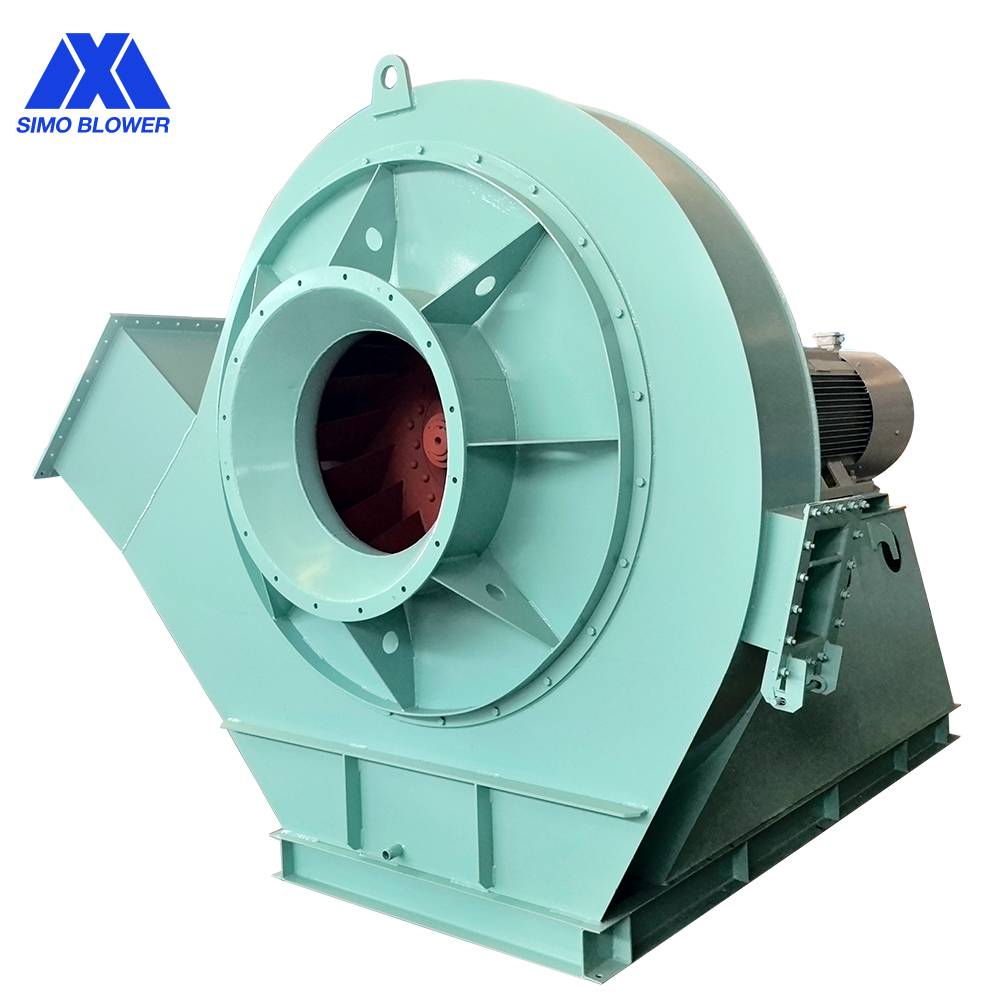

9-26 high-pressure fan is typically used for forging furnaces and high-pressure forced ventilation. It can also be widely used for material transport, air delivery, and conveying non-corrosive, non-combustible, non-viscous gases. The medium temperature generally does not exceed 50°C (maximum 80°C), and the dust and hard particles in the medium should not exceed 150 mg/m³. For the delivery of flammable or explosive gases, the impeller can be made of aluminum alloy to prevent sparks during operation, and the motor uses an explosion-proof type, with the same performance parameters as a standard motor. This fan has high efficiency, low noise, flat performance curves, and a wide high-efficiency range.

Product Features

①Capable of delivering higher gas pressure while providing more gas flow, with low noise.

②Installation is very simple with the use of an integrated bracket, requiring minimal support from specialized technicians.

③The motor shaft is elastically connected to the drive shaft, requiring less frequent belt tensioning or replacement, thus reducing maintenance workload.

④For systems with impellers under 1400mm in diameter operating at normal temperature, no additional bearing cooling device is required, reducing both user investment and maintenance efforts.

⑤When airflow resistance increases, the motor load automatically decreases to prevent motor burnout.

⑥Made of high-quality carbon steel, but can also be manufactured with stainless steel or other metals based on user requirements.

⑦After production, the fan undergoes operation testing and vibration value detection to ensure reliable performance.