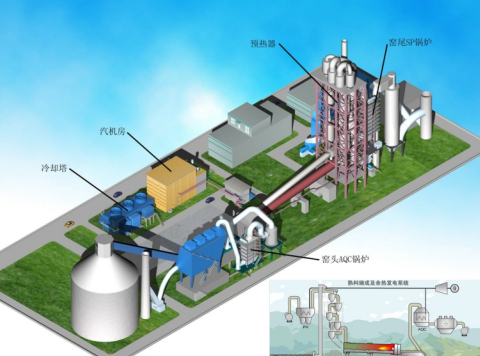

In pure low-temperature waste heat power generation systems, the heat source from cement kilns is divided into two parts: one part is the exhaust gas generated after the raw material is preheated by the kiln tail preheater, and the other part is the hot air from the clinker cooler at the kiln head. The waste gas from the kiln tail is relatively stable when the cement kiln production output remains consistent, and it contributes a significant portion of the heat in the system.

The Cement Kiln Waste Heat Boiler (Kiln Head and Kiln Tail) is designed by our company to meet the needs of waste heat recovery in clinker production in the cement industry. It is a pure low-temperature waste heat power generation boiler. The waste heat boilers for the kiln head (AQC) and the kiln tail preheater (SP) constitute the cement rotary kiln waste heat recovery boiler system.