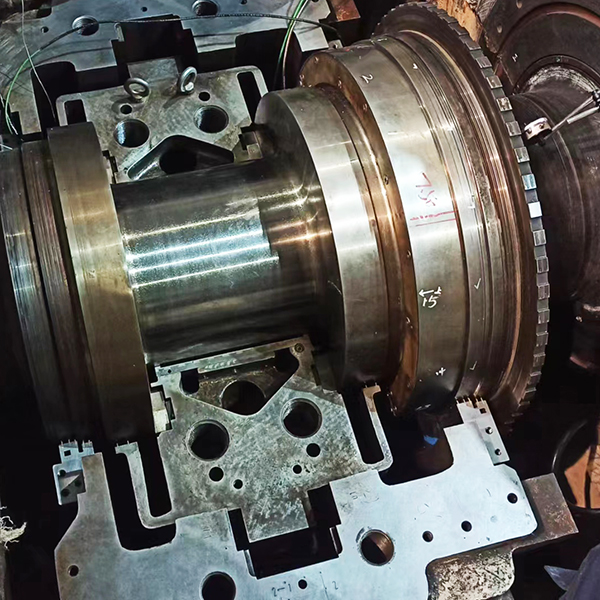

The new gas wall type sealing oil block has optimized design and good sealing effect, which solves the problems of water inlet and oil leakage in the steam turbine unit oil, and at the same time eliminates the impurities produced by the carbonized lubricating oil of high-temperature steam, and improves the operation of the steam turbine generator set The lubrication quality in the process improves the operation quality of the steam turbine generator set.

Product Features The main principle of XQYD type new gas wall seal oil block is to let dry compressed air enter the air chamber of the oil block, and then exhaust through the air groove on the air chamber, so that the compressed air forms an annular gas wall on the shaft diameter. The gas wall wraps the shaft diameter and prevents steam outside the bearing box from entering the oil system. It also blocks the splashed lubricating oil in the bearing box from approaching the direction of the oil block. The new air-stop sealing oil block solves water intake problems in the lubricating oil and emulsification of the lubricating oil by steam. The new air-stop sealing oil block adopts a non-contact air sealing method, which eliminates the carbon deposit problem at the tooth tip of the oil block, and will no longer cause problems such as grinding shaft and unit vibration caused by carbon deposit in the oil block. The gas wall type sealing oil block designed by our company is an annular gas wall formed by using compressed air to enter the oil block. The gas consumption is small, the cost is low, and the sealing effect can be achieved.