The heat exchanger is constructed by welding columns, upper and lower cover plates, connecting plates, spacer plates, and base plates to form the framework of the heat exchanger. The plate pairs are formed by welding the straight edges of two plates on opposite sides, and are positioned and fixed by four plug plates to form a unit.

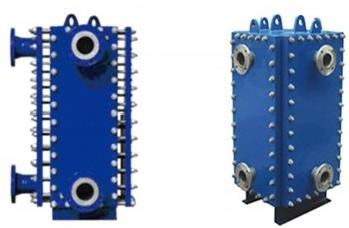

The heat exchanger is constructed by welding columns, upper and lower cover plates, connecting plates, spacer plates, and base plates to form the framework of the heat exchanger. The plate pairs are formed by welding the straight edges of two plates on opposite sides, and are positioned and fixed by four plug plates to form a unit. The adjacent plates between the plate pairs are welded together, and the plates near the upper and lower cover plates are welded to them. The plug plates are welded to the columns and upper and lower cover plates in the framework, and also welded to the plate pairs, forming the plate bundle component of the heat exchanger. The plate bundle component is connected to the fixed plates and sealing gaskets using double-headed studs, nuts, and flat washers to form the complete frame-type heat exchanger. This type of heat exchanger has advantages such as a high heat transfer coefficient, resistance to high temperatures and high pressures, flexible process configuration, strong adaptability to process systems, easy maintenance and cleaning, and a compact structure.