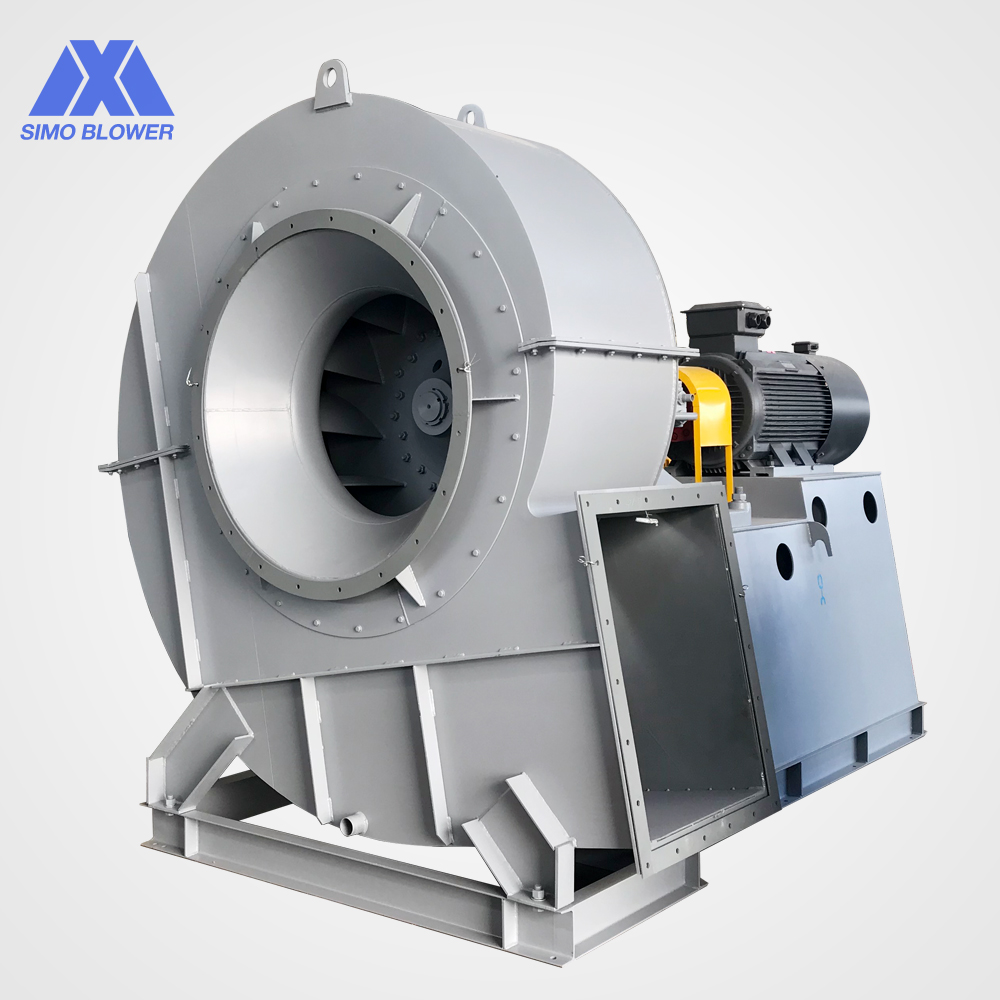

The 6-48 centrifugal induced draft fan is a dust-extraction fan specially designed by the fan industry. This series of fans features dust resistance, wear resistance, high efficiency, and low noise, making it suitable for a wide performance range. It is used for transporting gases containing dust, wood shavings, fine fibers, and other materials (if hard particles are present, a dust removal device should be installed before the fan). It can also serve as a general ventilation fan for air exchange.

Product Introduction:

The 6-48 centrifugal induced draft fan is a dust-extraction fan specially designed by the fan industry. This series of fans features dust resistance, wear resistance, high efficiency, and low noise, making it suitable for a wide performance range. It is used for transporting gases containing dust, wood shavings, fine fibers, and other materials (if hard particles are present, a dust removal device should be installed before the fan). It can also serve as a general ventilation fan for air exchange.

Product Features:

①Capable of outputting higher air pressure while providing greater gas flow.

②The fan speed can be flexibly set by pairing different pulley diameters, ensuring the fan operates at its highest efficiency point, reducing energy waste.

③Equipped with a motor sliding guide rail for easy belt tensioning, reducing energy loss caused by belt slack.

④The bearing housing has reserved positions for temperature and vibration sensors, making it easy to install a fan operation monitoring system.

⑤Uses liquid lubrication oil, with no need to open the bearing housing to change or refill the oil. The bearing housing features a viewing window for easy inspection of oil quality and levels.

⑥The bearing housing uses labyrinth-type mechanical seals with a unique oil leakage prevention design. The top has ventilation holes, and the seams are coated with sealing grease, completely eliminating the possibility of oil leakage.

⑦The impeller is annealed to fully eliminate internal structural stresses caused by welding, ensuring the impeller will not experience shape creep or develop cracks.

⑧The impeller undergoes high-standard dynamic balancing correction, ensuring stable fan operation.

⑨After production, the fan undergoes operational testing and vibration value checks to ensure reliable operation.