9-38 series fan has a large flow rate and moderate pressure. This fan is designed to ensure that the induced draft fan operates in the high-efficiency zone during variable operating conditions of industrial boilers, achieving energy-saving objectives. The fan is suitable for use with economizers (preheaters) and smoke and dust removal devices.

9-38 series fan has a large flow rate and moderate pressure. This fan is designed to ensure that the induced draft fan operates in the high-efficiency zone during variable operating conditions of industrial boilers, achieving energy-saving objectives. The fan is suitable for use with economizers (preheaters) and smoke and dust removal devices. It was jointly designed by national fan industry experts under the organization of the former Ministry of Machinery Industry's Fan Energy-saving Group, and is a high-efficiency and energy-saving product promoted by the State Economic and Trade Commission and the Ministry of Machinery Industry. The fan features high efficiency, low noise, flat performance curves, and a wide high-efficiency zone. It is suitable for industrial boilers with a capacity of 5 to 35 tons per hour, where the air intake conditions are similar and the performance matches, but the maximum temperature should not exceed 250°C. A dust removal device with an efficiency of no less than 85% must be installed in front of the induced draft fan to reduce the dust content of the flue gas entering the fan. This not only reduces the pollution caused by flue gas to the environment but also minimizes the wear of dust on the fan, contributing to the fan's longer lifespan.

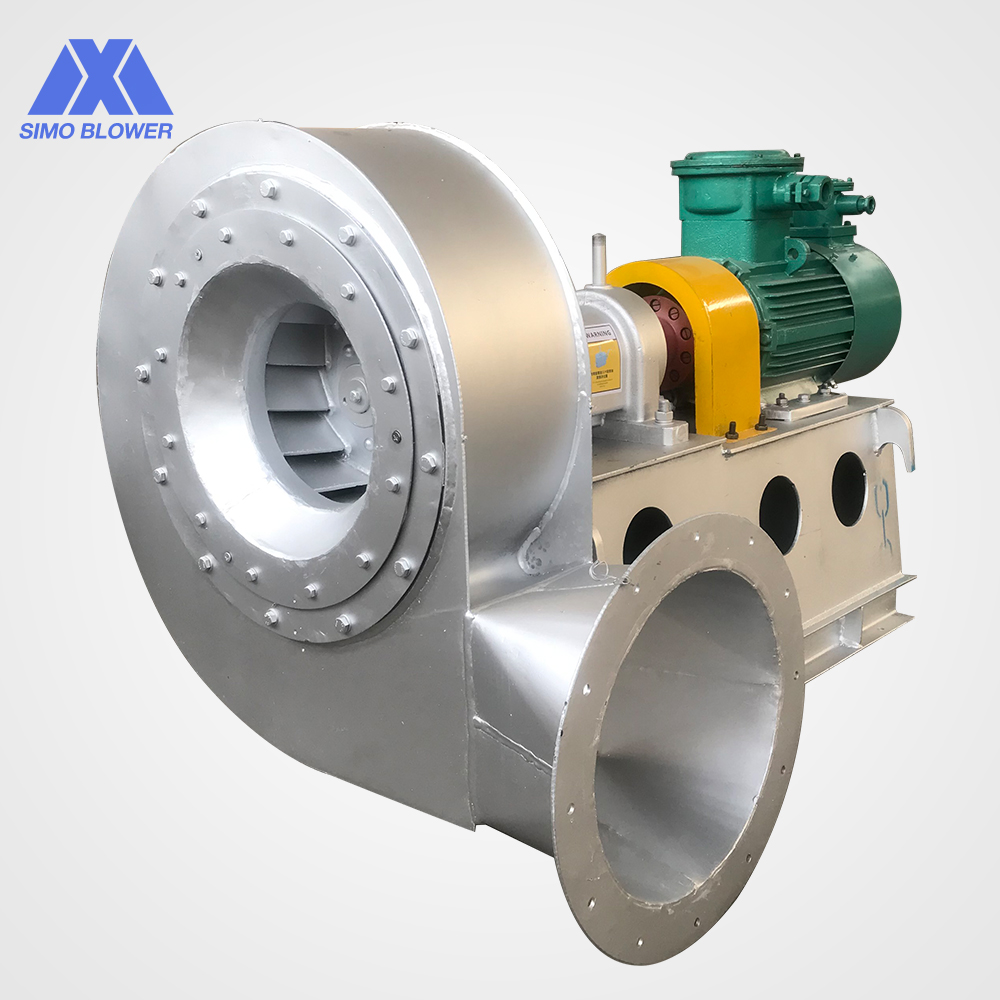

Product Features

①Capable of outputting high gas pressure while simultaneously providing more gas flow, with low noise.

②Simple installation with an overall bracket, requiring minimal support from professional technicians.

③The motor shaft is elastically connected to the drive shaft, eliminating the need for frequent belt tightening or replacement, reducing maintenance workload.

④Fan systems with impeller diameters below 1400mm operating at normal temperatures do not require additional bearing cooling devices, reducing user investment and maintenance workload.

⑤When air flow resistance increases, the motor load automatically decreases, preventing motor burnout.

⑥Manufactured using high-quality carbon steel, with optional stainless steel or other metal materials available upon customer request.

⑦Tested after production for operation and vibration values to ensure reliable operation.