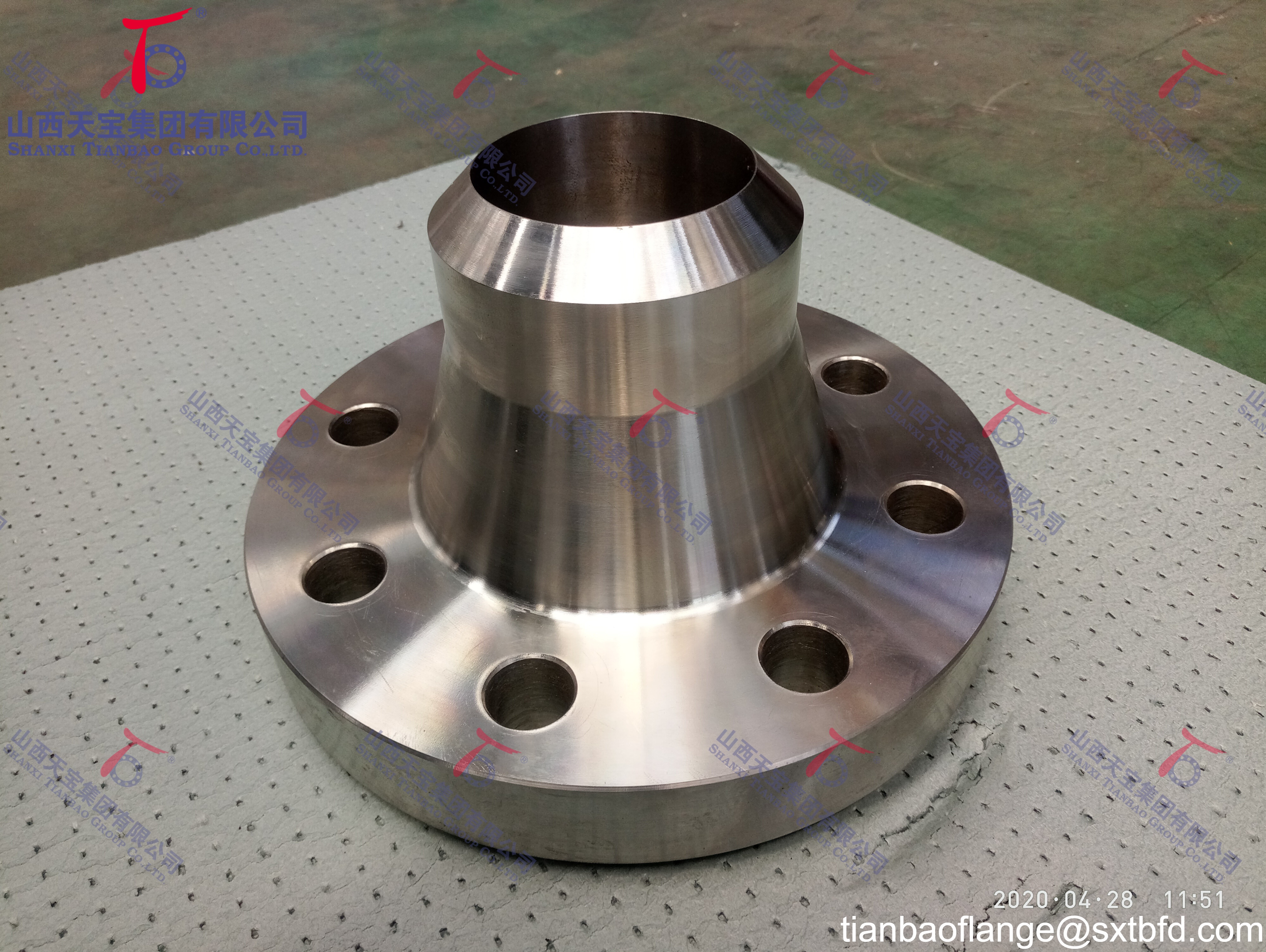

Long Weld Neck Flange, abbreviated as LWN Flange, is a specialized connector for high-pressure, high-temperature pipeline systems. Its core feature is the long tapered neck design, which effectively disperses pipeline stress, making it suitable for extreme working conditions such as high temperature, high pressure, and corrosive media.

Long Weld Neck Flange (LWN Flange)

Is a specialized connector for high-pressure, high-temperature pipeline systems. Its core feature is the long tapered neck design, which effectively disperses pipeline stress, making it suitable for extreme working conditions such as high temperature, high pressure, and corrosive media.

Various materials such as carbon steel like 10# and 20#, alloy steels like 16MnR and 12Cr1MoV, and stainless steels like ASTM A403 and 1Cr18Ni9Ti can be used. The pressure range follows international system standards, including PN2.5, PN6, PN10, PN16, PN25, PN40, PN63, PN100, and PN160 (MPa). Product sizes range from DN10 to DN2000 (mm). Sealing surface types such as flat (FF), raised face (RF), male-female face (MFM), tongue-and-groove face (TG), and ring joint (RJ) can be used based on actual requirements.

Long Weld Neck Flange is an important component in industrial pipeline systems. Its high strength, good sealing properties, and corrosion resistance make it the preferred choice for pipeline connections in high-temperature, high-pressure, and complex working conditions. In situations where safety and reliability are of utmost importance, it provides irreplaceable performance advantages, ensuring the stable operation of pipeline systems. It is one of the key components for ensuring safe and efficient industrial production.