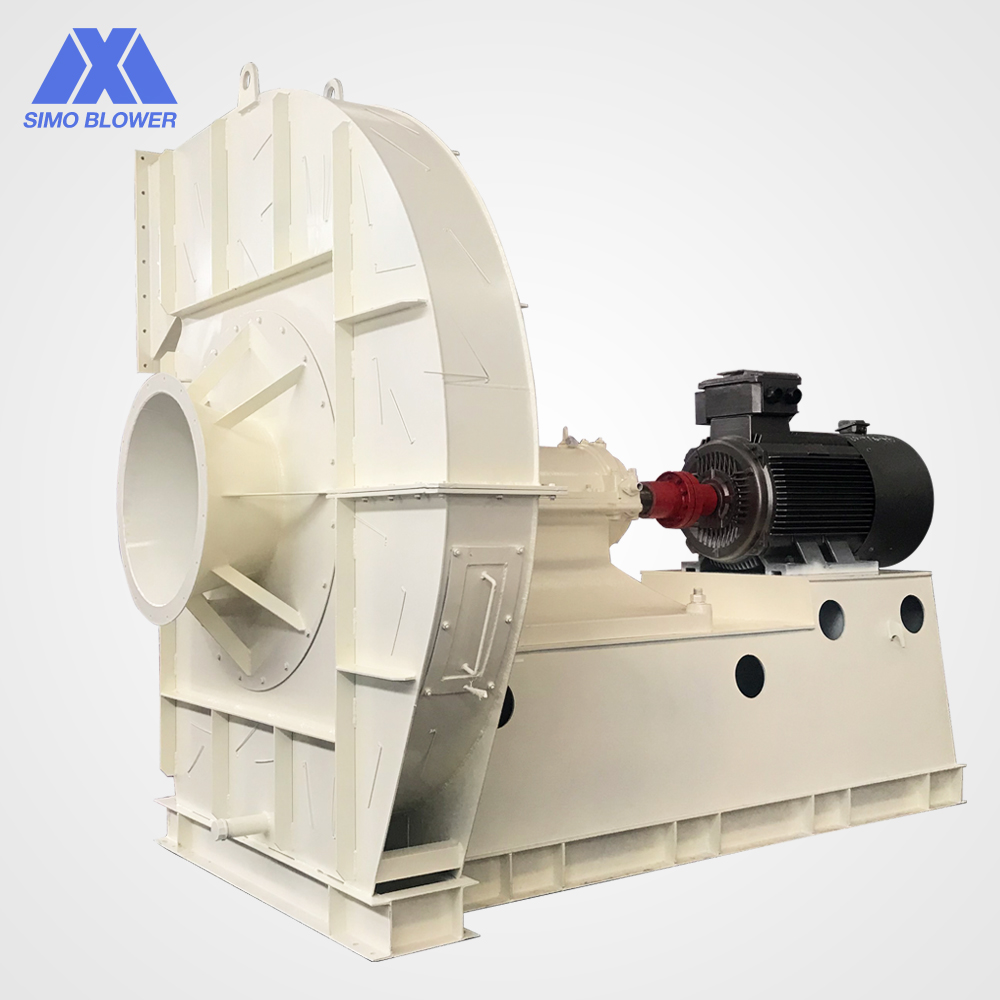

7-16 type high-pressure centrifugal fan is capable of delivering high output pressure and can transport various gases and materials at normal or high temperatures. It is suitable for use in harsh working conditions, such as conveying high-temperature/hazardous/dangerous gases, transporting coal dust, conveying hard particles/powders/debris/fibers, forced ventilation, industrial dust collectors, air filtration systems, flue gas desulfurization, flue gas denitrification, industrial boiler air supply and induced draft, material transport for various return kilns/calcinating kilns, air supply for smelting and casting furnaces, combustion support in blast furnaces, coal injection in blast furnaces, and pressurized transportation of gas, etc.

7-16 type high-pressure centrifugal fan is capable of delivering high output pressure and can transport various gases and materials at normal or high temperatures. It is suitable for use in harsh working conditions, such as conveying high-temperature/hazardous/dangerous gases, transporting coal dust, conveying hard particles/powders/debris/fibers, forced ventilation, industrial dust collectors, air filtration systems, flue gas desulfurization, flue gas denitrification, industrial boiler air supply and induced draft, material transport for various return kilns/calcinating kilns, air supply for smelting and casting furnaces, combustion support in blast furnaces, coal injection in blast furnaces, and pressurized transportation of gas, etc.

Product Features:

①Capable of delivering high output pressure and working at higher medium temperatures, suitable for industrial applications requiring high-pressure and high-temperature gas transportation.

②Compact in shape, saving installation space.

③Easy to install when using an integrated bracket, requiring minimal professional technical support.

④Made of high-quality carbon steel, with options for stainless steel or other metal materials upon request.

⑤Capable of handling dust-laden gases, from low to high dust concentrations, with specially treated blades achieving surface hardness of HRC60-70, extending impeller life by over three times.

⑥Tight fit between components, excellent sealing performance, ensuring that output pressure is not reduced.

⑦Impeller welds and main shaft undergo ultrasonic testing to ensure no welding defects or material flaws, ensuring strength.

⑧Impeller is dynamically balanced to high standards, ensuring stable fan operation.

⑨After production, it undergoes operational testing and vibration value detection, ensuring reliable performance.