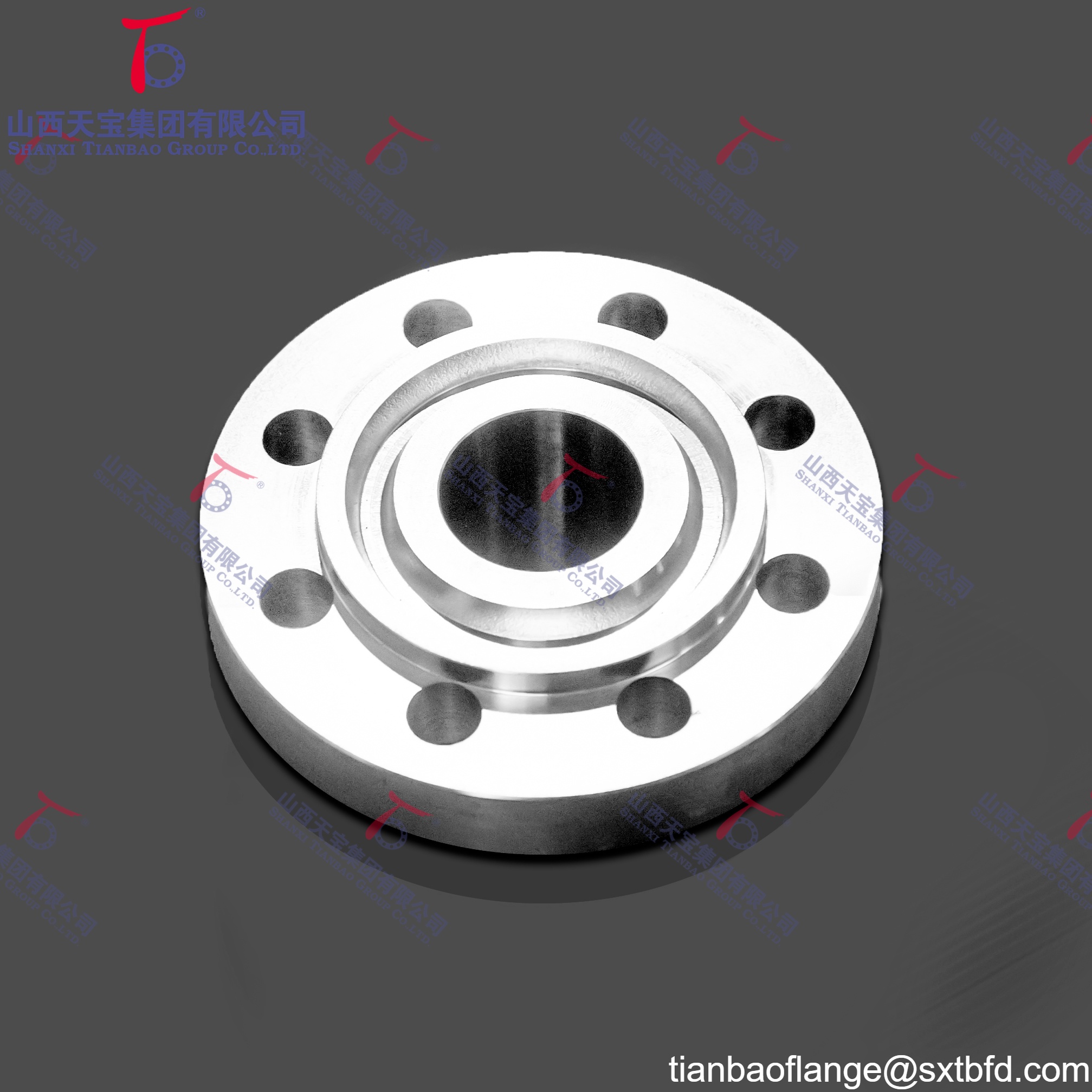

Socket welding flanges are fittings connected to pipelines through socket welding, mainly used in small diameter (typically DN50 and below), high-pressure, or high-temperature pipeline systems.

Socket Welding Flange

Is a fitting connected to the pipeline through socket welding, primarily used in small diameter (usually DN50 and below), high-pressure, or high-temperature pipeline systems. The design features a socket hole in the flange, where the pipe is inserted and secured by fillet welding, forming a stable seal. It is widely used in petrochemical, power, pharmaceutical, and other industries with strict sealing requirements.

It can be made from materials such as 10#, 20# carbon steel, A182F11, 12Cr1MoV alloy steel, and ASTM A403, 1Cr18Ni9Ti stainless steel. The pressure range follows international system standards, including PN2.5, PN6, PN10, PN16, PN25, and PN40 (MPa). The product size ranges from DN10 to DN50 (mm). Depending on actual needs, sealing face types may include flat (FF), raised face (RF), male-female face (MFM), tongue-and-groove face (TG), and ring-joint face (RJ).

With its high sealing performance, pressure resistance, and compact structure, the socket welding flange is an ideal choice for small diameter, high-pressure pipeline systems, particularly suitable for harsh working conditions in industries like petrochemical and power.