9-19 series centrifugal fan is capable of delivering high gas pressure and is suitable for transporting clean gases, combustible gases, corrosive gases, and gases with minor impurities, as well as light particles, debris, and short fiber materials.

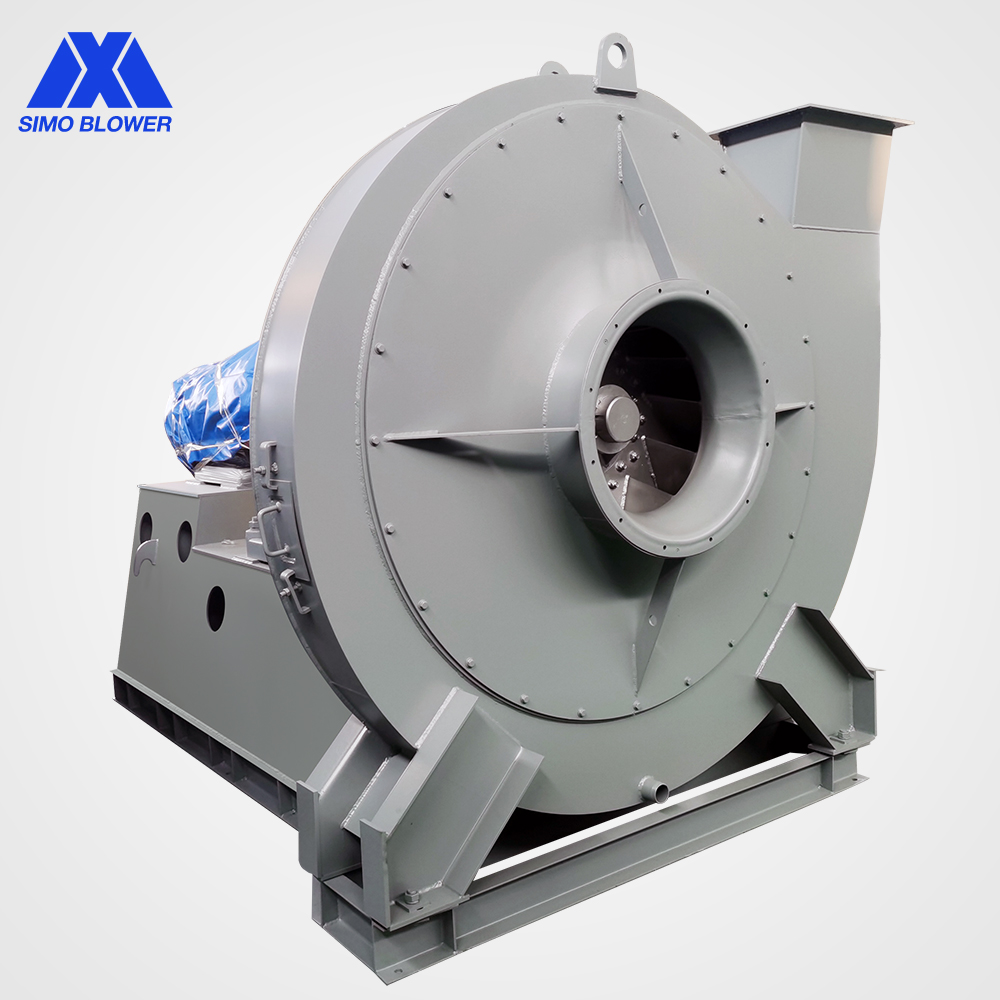

9-19 series centrifugal fan is capable of delivering high gas pressure and is suitable for transporting clean gases, combustible gases, corrosive gases, and gases with minor impurities, as well as light particles, debris, and short fiber materials. It is most commonly used in forced ventilation, rapid drying, rapid cooling, and heat dissipation applications, clinker cooling machines in cement production lines, circulating fluidized bed systems, air purification, industrial waste gas treatment, flue gas desulfurization, induced draft fans for industrial boilers or incinerators, primary and secondary air for blast furnaces, ventilation for large mill systems, industrial waste heat recovery devices, blast and air supply for metallurgical and casting furnaces, and pressurization of coal gas. The 9-08/9-19 fan series is among the most commonly used fan series in industrial fields by SIMO Fans.

Product Features

①Capable of delivering high output pressure and can operate at high medium temperatures, suitable for any industrial application requiring high-pressure and high-temperature gas transport.

②With the use of an integrated frame, installation is straightforward and typically does not require specialized technical personnel.

③The bearing housing is equipped with positions for temperature and vibration sensors, making it easy to install fan operation monitoring devices.

④When airflow resistance increases, the motor load will automatically decrease, preventing motor burnout.

⑤Custom designs based on client performance requirements, optimized using CFD technology, offering lower energy consumption than similar models.

⑥Tight component fit and good sealing performance ensure no reduction in output pressure.

⑦The impeller undergoes high-standard dynamic balancing, ensuring stable fan operation.

⑧After production, the fan undergoes operational testing and vibration value detection to ensure reliable operation.

⑨A wide range of optional accessories is available.