Slip-on flanges, with their simple structure, easy installation, low cost, reliable sealing, and strong adaptability, have become an indispensable component in industrial pipeline connections. They play a crucial role in various industrial fields and civilian building pipeline systems, meeting the pipeline connection needs in different working conditions.

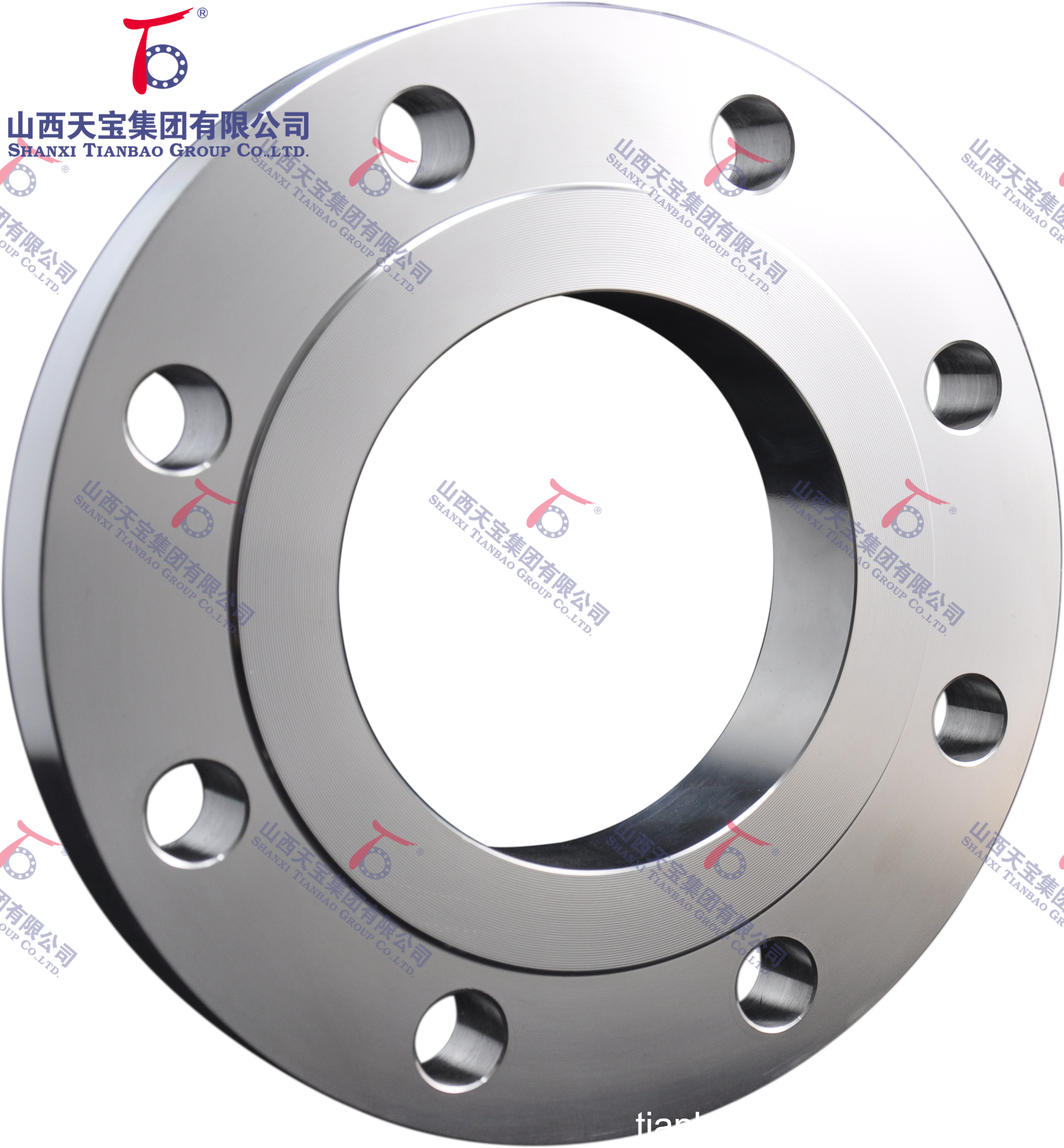

Slip-on Flange

Also known as necked flat-weld flange, is a common type of pipeline connection component. It consists of a flange plate, neck, and sealing face, offering excellent corrosion resistance, strength, and toughness. The flange can adapt to different working environments and medium requirements, widely used in low-pressure, ambient temperature pipeline systems.

Materials include carbon steels such as 10# and 20#, alloy steels like 16MnR and 12Cr1MoV, and stainless steels like ASTM A403 and 1Cr18Ni9Ti. The pressure range follows international standards from PN2.5, PN6, PN10, PN16, PN25, PN40, PN63, to PN100 (MPa). The product size ranges from DN10 to DN4000 (mm). Depending on specific requirements, sealing face types such as flat (FF), raised face (RF), convex-concave face (MFM), tongue and groove (TG), or ring joint face (RJ) are used.

Due to its simple structure, easy installation, low cost, reliable sealing, and strong adaptability, the slip-on flange is an essential part of industrial pipeline connections. It plays an important role in various industrial fields and civilian building pipeline systems, meeting the diverse pipeline connection needs under different working conditions.