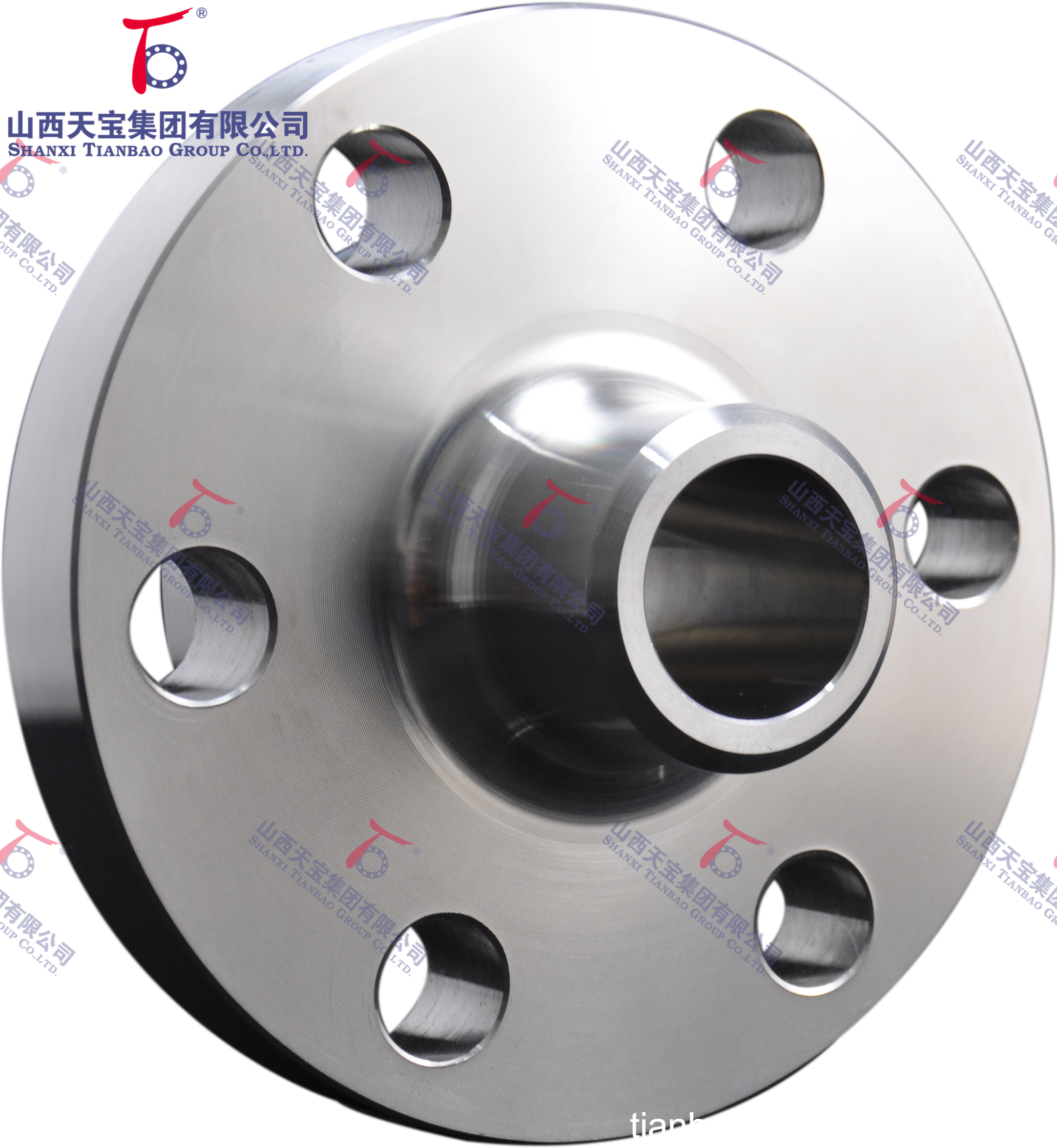

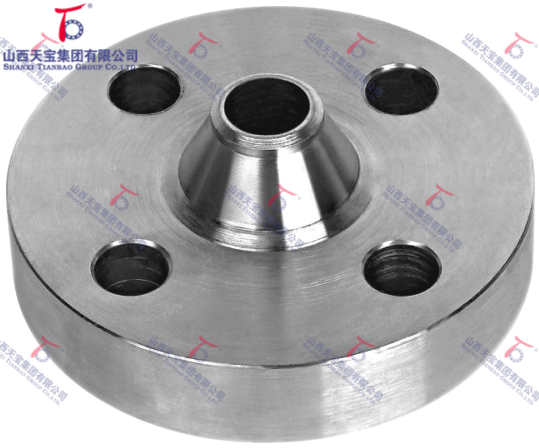

The reducing flange is a special type of flange used to connect pipelines with different diameters. It is primarily composed of a flange plate, sealing face, neck, and transition conical section. Through its unique structural design, it allows for smooth transitions between pipes of different diameters in a pipeline system.

The reducing flange is a special flange used to connect pipelines with different diameters. It is primarily composed of a flange plate, sealing face, neck, and transition conical section. Through its unique structural design, it allows for smooth transitions between pipes of different diameters in a pipeline system.

Depending on the medium characteristics, pressure ratings, and environmental conditions, materials such as Q235, 20# steel (carbon steel), 16Mn, 15CrMo (alloy steel), and 304, 316L (stainless steel) can be used.

The nominal pressure should match the system requirements. Common pressure ratings include low pressure and medium-high pressure, and can refer to ASME B16.5, EN 1092-1, or GB/T 9119 standards to ensure the flange thickness, bolt specifications, and pressure ratings are compatible.

The size of the reducing flange is determined by the combination of pipe diameters at both ends. The outer diameter and thickness increase according to standard specifications. The diameter change in the transition section can be progressive or abrupt, and the typical taper ratio is 1:3 (long radius) or 1:1 (short radius). Specific designs must be based on the fluid dynamics requirements of the pipeline system.

Depending on actual needs, sealing face types may include flat (FF), raised face (RF), ring-type joint (RTJ), and asymmetric sealing faces.

Through its tapered structure design and standardized sealing faces, the reducing flange efficiently enables diameter conversion and reliable sealing in pipeline systems. Its material selection, size compatibility, and pressure rating coverage make it widely used in industries such as chemical, energy, and shipbuilding.