9-28 high-pressure fan is commonly used in forge furnaces and high-pressure forced ventilation, and is widely used for material transportation. It is suitable for transporting air and non-corrosive, non-combustible, non-viscous gases. The temperature of the conveying medium generally does not exceed 80°C, and the dust and hard fine particles in the medium do not exceed 150mg/m³.

9-28 high-pressure fan is commonly used in forge furnaces and high-pressure forced ventilation, and is widely used for material transportation. It is suitable for transporting air and non-corrosive, non-combustible, non-viscous gases. The temperature of the conveying medium generally does not exceed 80°C, and the dust and hard fine particles in the medium do not exceed 150mg/m³. This fan can also be used as a high-temperature fan for special applications such as cement kiln external decomposition processes (machine number 16 and above) and steel smelting (with high heat-resistant, high-strength materials). The 9-28 high-pressure centrifugal induced draft fan is a newly developed, high-efficiency energy-saving product, and its performance fully meets the pneumatic performance of the general-purpose fan 9-26, with characteristics such as high efficiency, low noise, flat performance curve, large flow adjustment range, and wide high-efficiency zone.

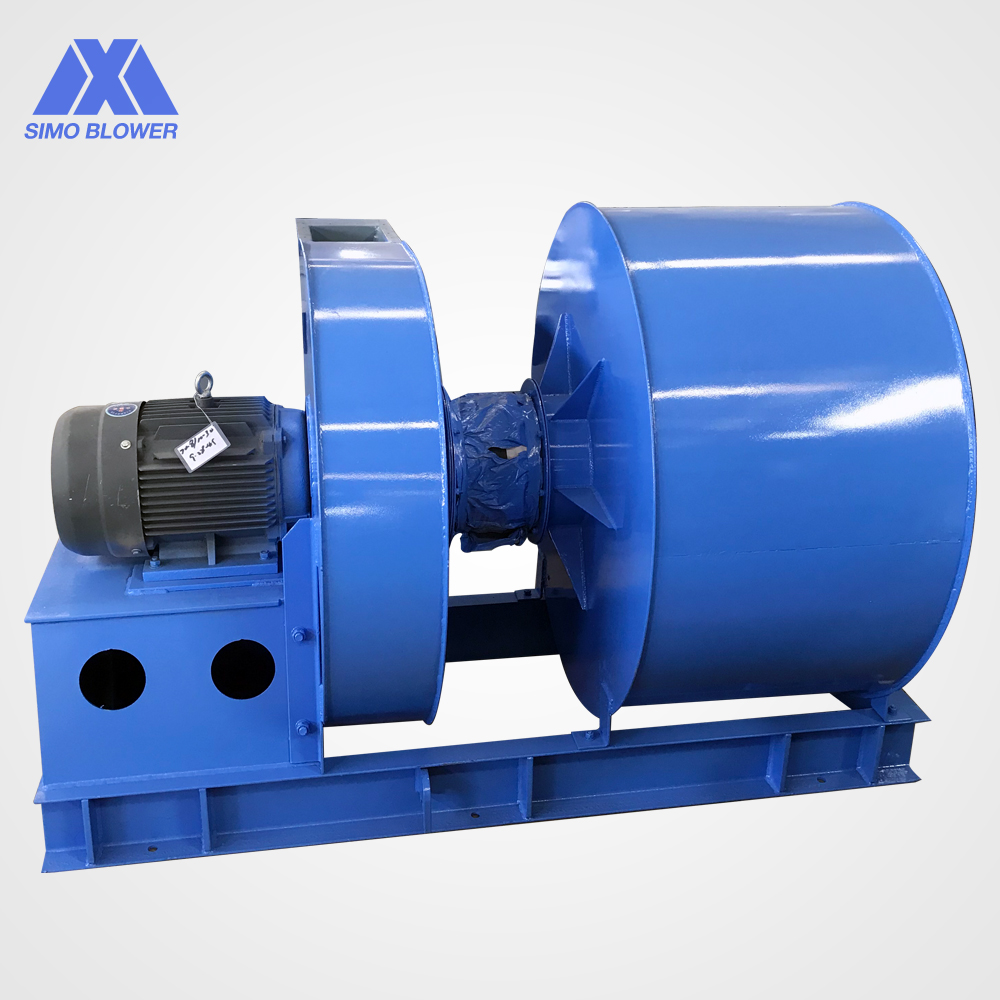

Product Features

①Capable of providing higher gas pressure while delivering more gas flow with lower noise.

②When using an integrated bracket, installation is very simple and does not require the support of professional technical personnel.

③The motor shaft and drive shaft are elastically connected, eliminating the need for frequent belt tensioning or replacement, reducing maintenance workload.

④Fan systems with an impeller diameter of 1400mm or less, operating at ambient temperature, do not require additional bearing cooling devices, reducing user investment and maintenance workload.

⑤As air resistance increases, the motor load automatically decreases, preventing motor damage.

⑥Made of high-quality carbon steel, but stainless steel or other metals can be used based on user requirements.

⑦After production, the fan undergoes operational testing and vibration detection to ensure reliable performance.